Slicer machine: everything you need to know

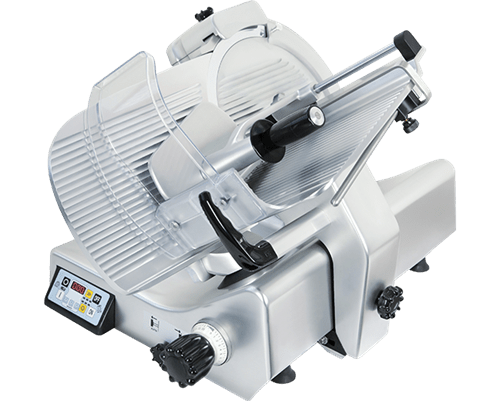

A slicer machine is a professional tool created to obtain thin and uniform slices from a wide range of food. Before you purchase a slicer machine, you need to know some basic information about its working mode, its features and the different models available on the market: not all the machines are the same, and you can optimize your investment by choosing the right slicer for your needs. Here is a guide to get your bearings in the world of slicer machines.

- The parameters for choosing a slicer machine

- The difference between manual and automatic slicing machines

- Gear driven and belt driven mechanisms

- Vertical and gravity meat slicer machines

- The diameter of the blade

- The kind of plate

- The cleaning of a slicer machine Manconi slicing machines: lines and models

- Manconi quality

The parameters for choosing a slicer machine

Professional slicer machines include many different models and it may be difficult to choose the right one at first glance. If you want to gain the sharpest result when slicing food, you should take into account every single detail of the machine you are about to purchase: all the details are a precise choice that depends on two basic elements:

- The kind of food to slice: it is not the same thing to slice frozen meat or creamy cheese, cold cuts or vegetables, bread or fresh meat. Specific slicing machines have been created to gain perfect slices with each type of food.

- The quantity and size of the food to slice: if you have to slice large amounts of food every day, you should choose a slicer machine with a reinforced cutting mechanism and top quality materials; on the other hand, if your slicing needs are lighter, you can gain excellent results even with a more standard machine.

Now we can start considering some basic distinctions that can help you choose the best slicer machines.

Manual and automatic slicing machines

In this guide, we will not talk about manual slicers. The reason is that manual machines are only suitable for non-professional contexts such as home kitchens, and we strongly suggest choosing an automatic model for any other application, even if you have a small food store. Automatic slicers are safer, quicker, more precise and optimized for cleaning, so they are also more hygienic. Thanks to their automatic mechanism, they take more time to tire the user and do not need particular strength to be used.

Gear driven and belt driven slicer machines

So, the first difference to take into account is between gear driven and belt driven slicer machines:

- Gear driven slicers have the most efficient and reliable slicing mechanism, ideal for activities that have to slice great amounts of food or particular hard ones. They are more expensive than average, but they are the best for high quality results, especially over time.

- Belt driven slicers have a standard slicing mechanism, which is perfect for smaller activities such as restaurants or food stores. They are less expensive but they give great results in standard situations.

Vertical and gravity slicer machines

We can find another major difference between vertical and gravity slicing machines:

- In vertical slicer machines, the plate is perpendicular to the blade. As a result, the product needs to be pushed against the blade by hand, but the slicing results are excellent as far as precision and uniformity are concerned, especially with meat. In addition, vertical slicers take less space than gravity ones. We recommend to choose vertical slicers for cutting fresh meat.

- In gravity slicer machines, the plate is slightly inclined and the product automatically slides towards the blade. Therefore, these slicers are usually easier to use even if they occupy more space than vertical models. Gravity slicers are recommended to slice cheese, deli, cold cuts and vegetables.

On the left: 300 VX VE (vertical slicing machine) by Manconi, on the right: 300 IX (gravity slicing machine) by Manconi

How to choose the diameter of the blade

One of the most important features to take into account is the diameter of the blade: you have to choose a value that fits the maximum size of the product you have to slice. The most common blade sizes are included between 250 and 370 mm: these values cover most of the slicing needs of both small and big activities.

Type of plate and blade coatings

We can now go into details. According to their use, slicer machines may have particular types of plates and special coatings on the blade. The plates can distinguish between meat-slicing optimized plates and generic plates for deli, cheese and cold cuts. The blades can have particular coatings that ease the slicing of specific products, i.e. Teflon coatings for the slicing of creamy cheeses.

How to clean your slicing machine?

Cleaning a slicer machine is as much important as choosing the right one. Careful cleaning ensures excellent results over time, increases the duration of the machine, guarantees hygiene and precision. When choosing a slicer, make sure it is realized with rust-resistant materials, so you will be able to wash it with a water jet without any risk of rusting. In addition, for better cleaning results you should choose a slicer that can be disassembled into its basic components, so you can clean them one by one separately. During the cleaning, always remember to pay the highest attention to the blade, as it is extremely sharp.

Detail of the blade exposed for cleaning procedure

Let’s see how to proceed:

- First, unplug the machine from the power socket;

- Dismantle the slicer machine by detaching every removable component;

- Remove the biggest food residuals with kitchen paper;

- Clean all the components with water and a neutral detergent: use both water jet and a non-scratch sponge;

- Rinse all the components with water, dry and re-assemble them;

- Check the status of the machine by switching it on.

Manconi slicer machines

Manconi is an Italian company that for almost sixty years has been designing and producing slicer machines for professional use. If you are looking for a top quality, reliable slicer for your activity, here is what we can offer to you.

Smarty Line

The SMARTY LINE includes professional slicers with an excellent quality price ratio, ideal for supermarkets, food stores, restaurants and deli stores. The slicers available are ideal to cut any kind of product, and can be chosen among all the features we have seen before. In addition, all the machines can be customized with the desired colors.

Here are some models from the Smarty line:

250 VX VE: a compact meat slicer machine equipped with a 250 mm blade diameter – also available with 300 mm. This model is perfect if you have to cut pork and other kinds of meat, but also vegetables and cheese.

300 VX BVC: due to its twin support arm with adjustable last-slice device, this meat slicer machine turns out to be the most suitable for raw ham and delicatessen. Among its best features there are perfect cut, easy cleaning and excellent movement of the carriage.

370 IX: thanks to its high quality material, this model is corrosion, shock and scratch resistant. It is a slicing machine suitable for vegetables, cheese and bread and for bigger products too.

Kolossal Line

The KOLOSSAL LINE includes all the top-range slicer machines of our production, recommended for food industries or professional activities that look for flawless results. Almost all these slicers are gear driven and guarantee the highest quality in slicing the recommended product. You can choose machines for any kind of product, from frozen meat to fresh meat, deli products, soft and creamy cheese, fish, cooked meat and pre-cooked products, bread and vegetables. Again, also these slicers are available with the features we’ve seen above.

Let’s have a look to some Kolossal slicer machines:

250 VK VE: this model is perfect for cutting meat and other products with small dimensions. Compact in size, it is a slicer machine with the same level of quality of other bigger models.

330 IK: optimized to reduce the operator strain, it is a model with great capacity and cutting precision. This slicer is particularly easy to clean since many of its parts are removable.

300 VK VE: this meat slicer machine is actually suitable for cutting delicatessen and cheese, meeting the needs of many customers. It is also available with a sliding carriage.

Kolossal Dual

The KOLOSSAL DUAL line is the latest evolution of the KOLOSSAL line, with aesthetic improvements and innovative endowments. Like the KOLOSSAL line, it is recommended for industrial activities and demanding professionals in the food sector.

Here are some Kolossal Dual slicer machines:

350 VK BV Dual: this model has been studied to maximise its ease of use, in addition to perfect cuts without product waste. The slicing machine is great for cutting every kind of delicatessen, in particular ham. It can be easily dismantled and assembled for a perfect and simple cleaning.

370 VK TC Dual: this is a vertical meat slicer machine with high cutting capacity, that guarantees perfect meat slices without food waste. It is very compact and usable also in limited spaces.

New Kolossal Dual 330 VK FA: the newest Manconi’s slicing machine is fully automatic but with manual options too. It is provided with a touch screen display where you can choose slice programs, check errors and other operations.

All the slicing machines by Manconi:

- Are automatic: quick and easy to use

- Are certified according to the EU regulations

- Are safe and reliable over time

- Are realized with rustproof materials

- Are available with removable components

- Are studied with ergonomic features

Manconi quality for excellent slicer machines

Our production process includes many quality controls. The aim is always to achieve excellence and innovation, the main principles in our vision and mission since we started producing slicer machines.

Manconi slicing machines are designed and produced to help people in their work, reducing their strain and preserving their safety. This quality has been recognized by many certifications by national and international institutes (NSF, UL,…) that make us really proud of our work during all these years.

Are you interested in high-quality slicer machines?