At Manconi's you can find several models of single-phase slicer characterized by excellent cutting precision and excellent quality of materials.

In this article we will see:

- Recommended models by Manconi

- Manconi's single-phase slicer lines

- What’s the difference between a single-phase and a three-phase slicer?

- Why rely on Manconi

Some models recommended by Manconi

Let us now look at some recommended single-phase slicer models for each line:

Kolossal line

Regarding the Kolossal line, Manconi recommends:

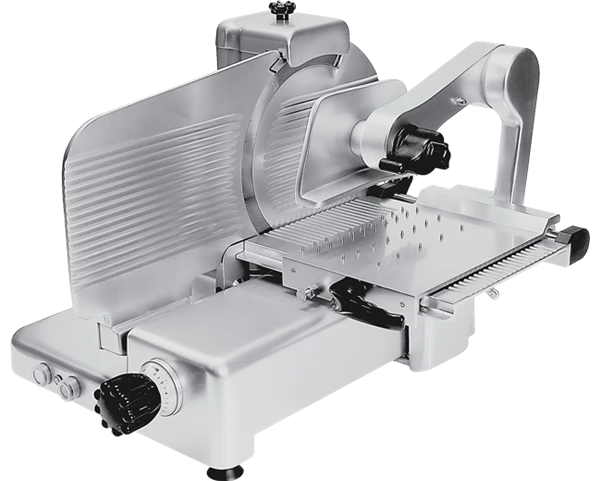

250 IK is a single-phase inclined slicer perfect for slicing cold cuts, cheeses and precooked meats. It is a flexible and space-saving machine and is perfect for slicing foods that are not large in size. It takes up very little space and can be installed in confined areas.

250 IK is a single-phase inclined slicer perfect for slicing cold cuts, cheeses and precooked meats. It is a flexible and space-saving machine and is perfect for slicing foods that are not large in size. It takes up very little space and can be installed in confined areas.

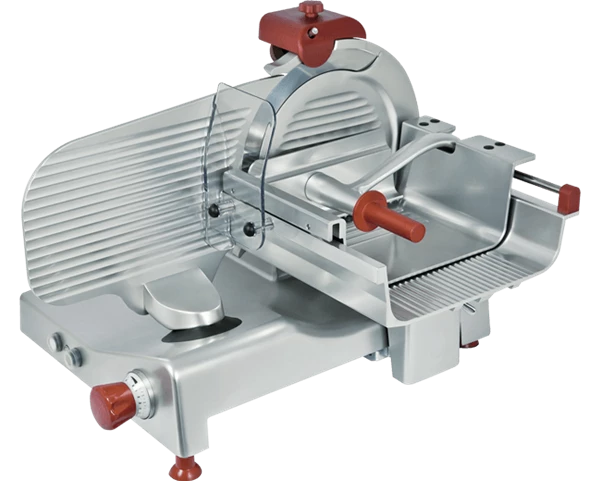

330 IK is another single-phase model in the Kolossal line that is very versatile. In fact, it is ideal for slicing sausages of all kinds, cold cuts, vegetables, bread, and cheese. This machine offers great cutting capacity and precision and has a greatly reduced loading height of the goods to minimize operator fatigue. Finally, it can be accessorized with different types of plates.

330 IK is another single-phase model in the Kolossal line that is very versatile. In fact, it is ideal for slicing sausages of all kinds, cold cuts, vegetables, bread, and cheese. This machine offers great cutting capacity and precision and has a greatly reduced loading height of the goods to minimize operator fatigue. Finally, it can be accessorized with different types of plates.

300 VK BV: this single-phase slicer is the ideal solution for slicing ham and other cured meats. This vertical slicer is designed for precision and ease of use and offers an ingenious and reliable merchandise clamping mechanism. The tilting, contoured last-slice-device adapts perfectly to the shape of the products, ensuring uniform, high-quality slices. Perfect for those looking for an efficient and versatile single-phase slicer, the 300 VK BV is an excellent choice for butcher shops, delicatessens and restaurants.

300 VK BV: this single-phase slicer is the ideal solution for slicing ham and other cured meats. This vertical slicer is designed for precision and ease of use and offers an ingenious and reliable merchandise clamping mechanism. The tilting, contoured last-slice-device adapts perfectly to the shape of the products, ensuring uniform, high-quality slices. Perfect for those looking for an efficient and versatile single-phase slicer, the 300 VK BV is an excellent choice for butcher shops, delicatessens and restaurants.

Kolossal Dual line

Here now are some recommended models from the Kolossal Dual line:

350 IK Dual: This is a single-phase slicer suitable for cutting cold cuts, cheese, and precooked meats. Its inclined product holder plate facilitates the operator's work and ensures greater cutting precision. Its rounded shapes facilitate cleaning operations, which can be safely carried out by water jet.

350 IK Dual: This is a single-phase slicer suitable for cutting cold cuts, cheese, and precooked meats. Its inclined product holder plate facilitates the operator's work and ensures greater cutting precision. Its rounded shapes facilitate cleaning operations, which can be safely carried out by water jet.

370 VK BV Dual is ideal for cutting cold cuts and ham. It guarantees high precision, and its compact dimensions make the best use of available space. The merchandise locking mechanism is simple and reliable, and each detail is designed to simplify the use of the slicer to minimize product waste.

370 VK BV Dual is ideal for cutting cold cuts and ham. It guarantees high precision, and its compact dimensions make the best use of available space. The merchandise locking mechanism is simple and reliable, and each detail is designed to simplify the use of the slicer to minimize product waste.

Kolossal Dual 330 VK FA: This single-phase, fully automatic slicer represents innovation in the slicing machine industry. With its touchscreen display, you can program and store cuts, perform error diagnostics, and easily access operating and maintenance instructions. With Wi-Fi and custom configuration features, this slicer offers a versatile and modern user experience. Ideal for cutting large quantities of meats, meats, and cheeses with precision and ease, it provides the highest level of safety and hygiene without requiring operator intervention.

Kolossal Dual 330 VK FA: This single-phase, fully automatic slicer represents innovation in the slicing machine industry. With its touchscreen display, you can program and store cuts, perform error diagnostics, and easily access operating and maintenance instructions. With Wi-Fi and custom configuration features, this slicer offers a versatile and modern user experience. Ideal for cutting large quantities of meats, meats, and cheeses with precision and ease, it provides the highest level of safety and hygiene without requiring operator intervention.

Smarty line

To conclude, here are some suggestions for the Smarty line:

250 VX VE is perfect for slicing meat, cold cuts, vegetables, and cheese. This single-phase model with compact dimensions guarantees great performance, thanks in part to the smoothness of the carriage that improves cutting precision. Efficient and safe, this machine is durable and quality and requires quick and easy maintenance.

250 VX VE is perfect for slicing meat, cold cuts, vegetables, and cheese. This single-phase model with compact dimensions guarantees great performance, thanks in part to the smoothness of the carriage that improves cutting precision. Efficient and safe, this machine is durable and quality and requires quick and easy maintenance.

370 IX thanks to this model, it is possible to slice a wide variety of products such as sausages, cold cuts, bread, cheese, vegetables, and precooked foods, even large-sized ones. The smooth sliding of the carriage allows easy cutting without product waste. The materials used are resistant to impact, abrasion, and corrosion, ensuring maximum hygienic safety.

370 IX thanks to this model, it is possible to slice a wide variety of products such as sausages, cold cuts, bread, cheese, vegetables, and precooked foods, even large-sized ones. The smooth sliding of the carriage allows easy cutting without product waste. The materials used are resistant to impact, abrasion, and corrosion, ensuring maximum hygienic safety.

350 VX TC: This single-phase slicer is the ideal solution for cutting fresh meat, ensuring comfortable and safe use. With its controlled and regular cutting, it is perfect for slicing all kinds of meat. Made of new materials resistant to impact, abrasion and corrosion, it ensures maximum hygienic safety. Easily removable parts allow for quick and thorough cleaning. Efficient, reliable and designed for long-lasting use, the Smarty 350 slicer is available in elegant red or black colored versions, ideal for everyday use.

350 VX TC: This single-phase slicer is the ideal solution for cutting fresh meat, ensuring comfortable and safe use. With its controlled and regular cutting, it is perfect for slicing all kinds of meat. Made of new materials resistant to impact, abrasion and corrosion, it ensures maximum hygienic safety. Easily removable parts allow for quick and thorough cleaning. Efficient, reliable and designed for long-lasting use, the Smarty 350 slicer is available in elegant red or black colored versions, ideal for everyday use.

Learn more about our single-phase slicers!

Manconi's single-phase slicer lines

Manconi has made as many as three lines of efficient, precise, and state-of-the-art single-phase slicers: Kolossal, Kolossal Dual, and Smarty.

- Kolossal: is Manconi'stop line and encapsulates both the tradition that has always characterized the company and the innovation that allows it to keep up with market needs. This line is perfectly capable of guaranteeing the minimum product waste and the highest quality in terms of operator safety as well;

- Kolossal Dual: it is a reinterpretation of some models in the Kolossal line through a fresher, more modern design characterized by rounded shapes. The term "Dual" indicates a choice of built-in or separate sharpener and belt or gear transmission;

- Smarty: this line is the latest big news from Manconi and consists of a series of durable, compact slicers with a very attractive design. These models are particularly suitable for public display and thus for the Ho.Re.Ca. sector.

What’s the difference between a single-phase and a three-phase slicer?

Which model is best for you—single-phase or three-phase? What are the main features when choosing the right slicer for your daily needs?

The first distinction is in electrical supply. While single-phase slicers operate on standard 220-240V electrical currents, three-phase slicers require a higher 380-400V power supply, making them more suitable for industrial applications.

Additionally, three-phase models provide more power for continuous, intensive operation without straining the motor. This makes them more energy-efficient in the long run compared to single-phase slicers, which are an excellent solution for smaller businesses with limited space.

Here’s a summary of the main operational differences between single-phase and three-phase machines:

| Feature |

Single Phase Slicer

|

Three-Phase Slicer |

| Voltage | 220-240 V |

380-400 V

|

| Usage Environment | Small businesses | Industrial, and professional kitchens |

| Usage Intensity | Moderate with intervals | intensive, continuous use |

| Energy Cost | Higher with equal usage time | Lower over the long term |

Need a single-phase slicer for your business?

Contact us for more information

Why rely on Manconi

At Manconi's you can find not only all of our exclusive single-phase slicers but also a range of additional options for even better cutting performance.

But that's not all. Choosing Manconi slicers is advantageous because:

- They are easy to use, make the operator's work as easy as possible, and achieve flawless cuts effortlessly, quickly but above all without risk;

- They are made with the best materials, resistant to shocks and abrasions but above all extremely safe from a hygienic point of view;

- They require very little maintenance;

- The design is modern and visually attractive, a factor that makes them perfect for any context and therefore extremely versatile.

Need help finding the right single-phase slicer for your needs?

Leave your comment