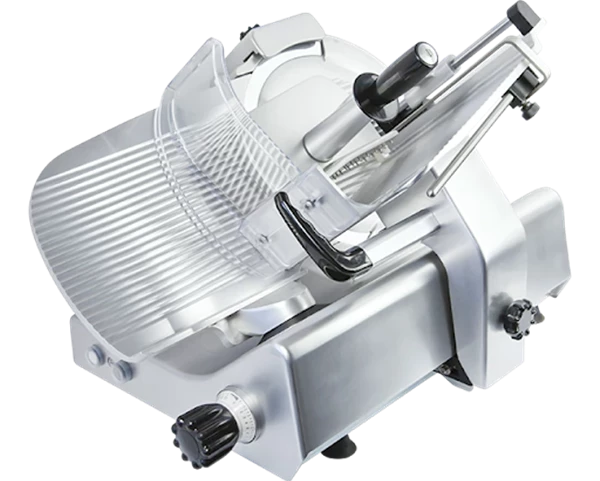

Whether it's a supermarket, butcher shop, deli, or restaurant, one common element in all these businesses is the meat slicer. However, these machines must comply with legal standards to ensure operators can work safely.

In this article, you will learn:

- What are the main meat slicer safety standards?

- Why is CE marking important?

- All Manconi meat slicers are compliant

What are the main meat slicer safety standards?

Specific safety standards must be considered to verify if your professional meat slicer is compliant. These are a series of European directives regulating the quality standards for the design and production of machines in terms of materials, hygiene practices, and safe usage instructions.

Let’s explore the main standards.

Directive 2006/42/EC

Also known as the Machinery Directive, it includes all safety indications that apply to fixed, mobile, transportable, or liftable machinery, except for some devices listed within the same regulation.

Directive 89/392/EEC

This European directive establishes what safety devices a meat slicer must have to be considered compliant. It also defines preventive measures to avoid accidents and injuries during the use of the equipment.

Directive 1935/2004/EC

Effective since 2004, this standardconcerns materials or objects intended to come into direct or indirect contact with food to ensure their suitability, aiming for higher safety levels for the end consumer.

EN 60335-2-64:2021

Effective from 2021, this standard replaces CEI EN 60335-2-64:1998 concerning electric kitchen machines for collective use. The text addresses hygiene and the noise produced by these instruments.

This standard applies to all appliances that can operate without additional components and are delivered in various assemblable parts for logistical reasons.

EN 1974:1998+A1:2009

This standard specifies the safety and hygiene features necessary for the design and production of meat slicers with:

- A motor-driven circular blade;

- A diameter over 150 mm;

- An alternating motion carriage.

Industrial meat slicers are not evaluated as they are used in meat processing industries and slaughterhouses, which are fixed by definition.

EN 60204-1

This standard addresses machinery safety, focusing on command responses, device usability, and best practices for effective maintenance.

Why is ce marking important?

Before being marketed within the European Union, many products must receive CE marking. This mark certifies the product's compliance with EU standards regarding safety, health, and environmental protection.

Applying the CE mark on meat slicers verifies that the machine is compliant. To achieve this, the slicer must:

- Reduce the risk of accidents and injuries for operators;

- Ensure the use of materials suitable for food contact;

- Enhance machine efficiency in energy and operation;

- Assure the legal compliance of the meat slicer, making it suitable for commercial use;

- Feature a compact and edge-free design for easy cleaning;

- Adopt safety buttons and blade guards.

It's important to note that the manufacturer is solely responsible for the declaration of conformity, and no license is required to obtain it.

How to obtain ce marking for a meat slicer?

The first step is to examine the meat slicer to ensure it meets all relevant European requirements. Then, determine if the machine can be independently evaluated or if a verified body is needed.

The final steps involve preparing a dossier that includes all compliance documents and the technical specifications of the device. Once all these steps are completed, you can draft and sign an EU declaration of conformity.

All Manconi slicers bear CE markings and are up to standard.

All Manconi meat slicers are compliant

Manconi is renowned for its quality and reliable meat slicers' safety features. All our models comply with European safety and hygiene directives.

By choosing a Manconi device, you can rely on a machine equipped with:

- Removable sharpener, blade cover, slice guard, and press to ensure thorough cleaning;

- Aluminum surfaces suitable for food contact and MOCA-certified machines;

- Goods holder device for optimal grip on the product to be sliced;

- Auto-lock device to prevent accidents and protect operators.

Manconi produces meat slicers compliant with current European safety standards, offering an impeccable slicing experience with safe and high-performing devices.

Do you need more information on our meat slicer safety feature?

Leave your comment